Table of Contents

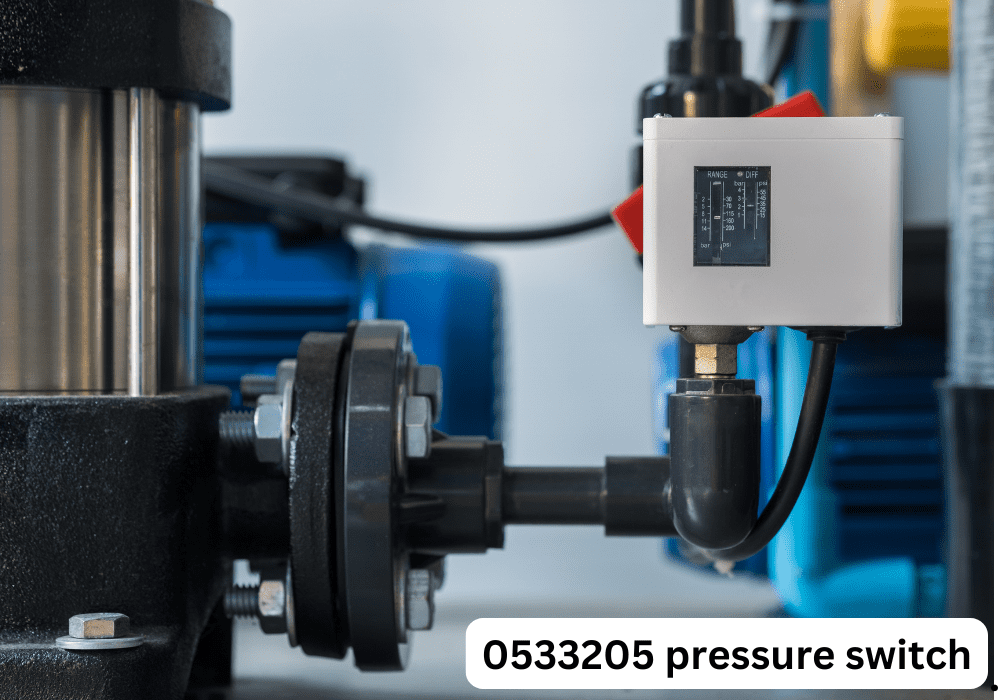

Introduction to the 0533205 Pressure Switch

Pressure switches play a crucial role in many industrial applications, from HVAC systems to automotive machinery. The 0533205 hot tub pressure switch is one such critical component, designed to monitor pressure levels within systems and ensure safety, efficiency, and optimal performance. Whether you are maintaining industrial equipment, installing an HVAC system, or working in fluid mechanics, understanding the 0533205 pressure switch is essential for seamless operations.

In this guide, we will dive deep into the technical aspects of the 0533205 hot tub pressure switch explore its functionality, discuss its various applications, and explain why this particular switch is a popular choice in industrial systems. From installation to maintenance, we cover everything you need to know to make the most of this reliable and effective tool.

What is a 0533205 Pressure Switch?

The 0533205 pressure switch is a device designed to detect and respond to changes in pressure levels in a system. It functions by opening or closing an electrical contact when a specific pressure point is reached. This action can either activate or deactivate a device or system based on the pressure conditions, ensuring that systems do not exceed safe operating limits.

Pressure switches like the 0533205 are widely used across industries to control various operations such as pump cycling, HVAC system regulation, and pneumatic equipment. They serve as safety devices to prevent over-pressurization or under-pressurization, which can lead to system failures or inefficiencies.

Key Components of the 0533205 Pressure Switch

- Pressure Sensing Element: This component detects the pressure level in the system. In the case of the 0533205 pressure switch, this could be a diaphragm or a piston, depending on the type of switch and the application.

- Adjustable Spring Mechanism: The spring sets the pressure at which the switch activates. This allows users to set a specific threshold for pressure control.

- Electrical Contacts: These are responsible for opening or closing the electrical circuit when the pressure threshold is reached.

- Enclosure: The pressure switch is housed in a durable casing that protects the internal components from environmental factors such as dust, moisture, and heat.

How Does the 0533205 Pressure Switch Work?

The operation of a 0533205 hot tub pressure switch is fairly straightforward. It operates by detecting the pressure of gas or liquid in a system. When the pressure reaches a preset value, the internal mechanism actuates the electrical contacts to either open or close a circuit. This action either starts or stops the equipment connected to the switch, preventing damage from overpressure or maintaining proper pressure levels.

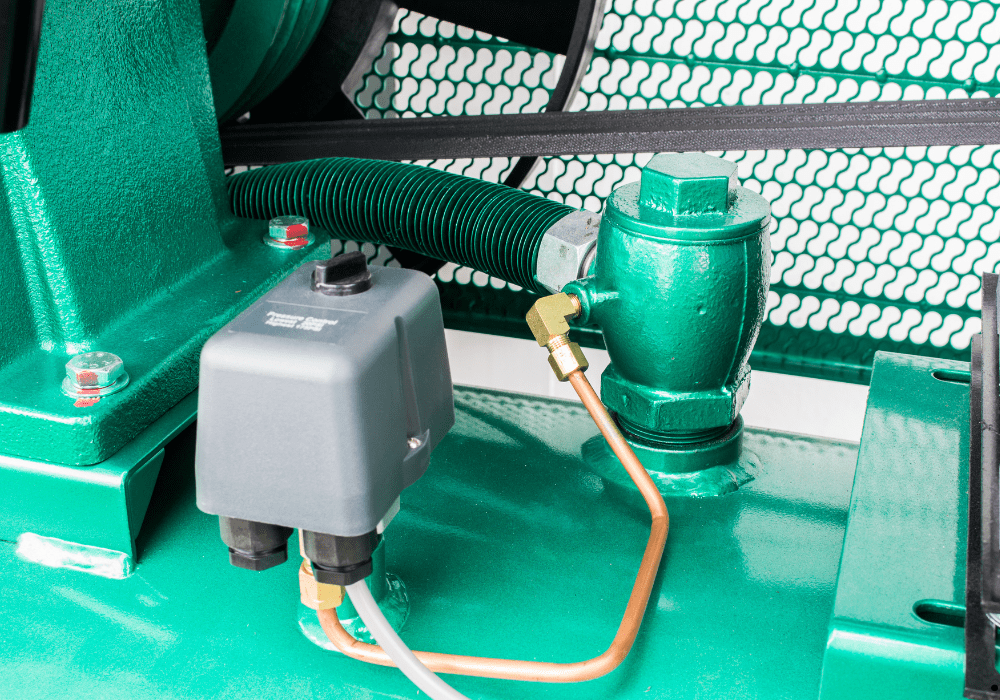

For example, in an air compressor system, the pressure switch may shut down the compressor when the tank reaches its maximum allowable pressure, thereby ensuring safe operation.

Applications of the 0533205 Pressure Switch

The 0533205 pressure switch has a broad range of applications across various industries. Its ability to precisely control pressure makes it indispensable in both industrial and commercial environments. Below are some of the key sectors where this pressure switch is commonly utilized:

HVAC Systems

One of the most common applications of the 0533205 pressure switch is in HVAC (Heating, Ventilation, and Air Conditioning) systems. These switches are used to control air pressure within ducts and ventilation systems. In an HVAC system, maintaining proper pressure is critical to ensuring airflow efficiency and preventing damage to equipment.

By regulating the compressor and blower motors, pressure switches help maintain the balance of heating and cooling in buildings. The 0533205 pressure switch ensures that air conditioners, heaters, and ventilation systems operate within safe pressure limits, preventing the risk of system failure due to pressure imbalances.

Water Pumps and Fluid Systems

In water pump systems, a 0533205 pressure switch is responsible for starting or stopping the pump based on the system’s pressure. When the pressure falls below a certain level, the switch closes the circuit and activates the pump to maintain adequate water supply. Similarly, when the pressure rises too high, the switch deactivates the pump to prevent damage or system inefficiency.

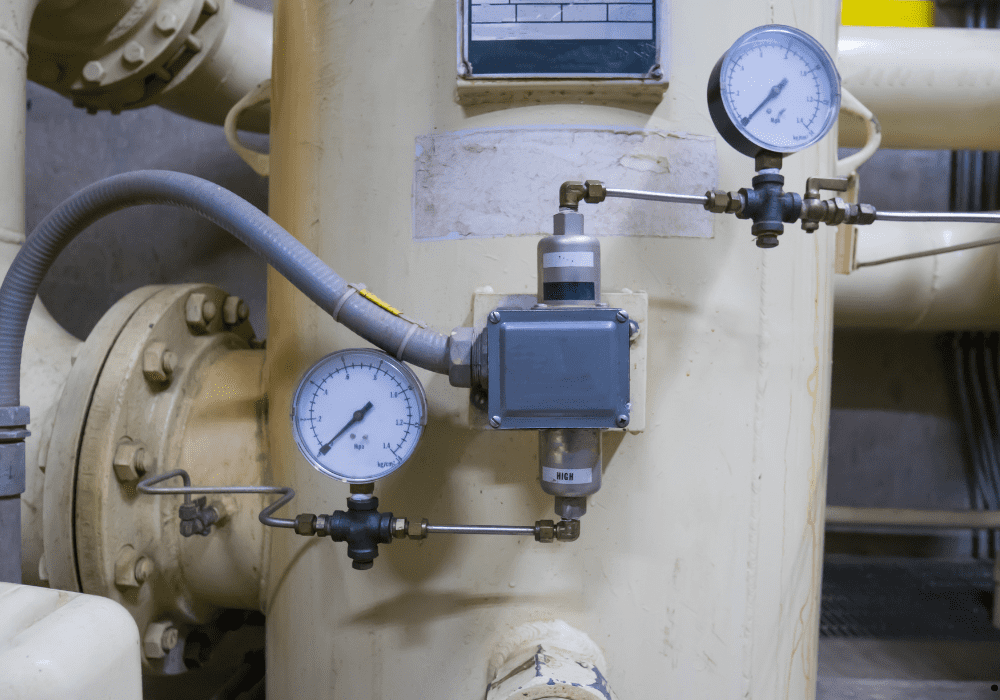

Pneumatic and Hydraulic Systems

Pneumatic and hydraulic systems rely heavily on precise pressure control. The 0533205 pressure switch ensures that these systems do not operate under dangerously high or low pressure conditions, which could result in equipment malfunctions or failures. In such systems, the switch acts as a safety mechanism, protecting vital machinery from over-pressurization and avoiding catastrophic damage.

Automotive Industry

In the automotive industry, the 0533205 hot tub pressure switch is used in various vehicle systems, including braking and air conditioning. In braking systems, pressure switches monitor the pressure in hydraulic lines, ensuring the correct pressure is applied for safe braking performance. Similarly, in vehicle air conditioning units, the pressure switch monitors refrigerant levels to maintain optimal cooling and prevent system overloading.

Industrial Machinery

In heavy-duty machinery, maintaining the correct pressure in hydraulic and pneumatic systems is crucial for safe operation. The 0533205 hot tub pressure switch can be found in a wide array of industrial equipment, ensuring that the machinery operates within the designated pressure range to avoid damage, inefficiencies, or hazardous working conditions.

Advantages of the 0533205 Pressure Switch

The 0533205 pressure switch offers several advantages, which make it a reliable and preferred choice for many industries. Below are the key benefits:

Precise Pressure Control

The primary advantage of the 0533205 pressure switch is its ability to provide accurate pressure monitoring and control. Whether used in an HVAC system or a hydraulic machine, this switch ensures that pressure levels remain within safe operating limits, thus optimizing performance and extending the lifespan of the equipment.

Safety

By preventing overpressure or underpressure conditions, the 0533205 pressure switch plays a crucial role in maintaining safety across a variety of systems. In systems like water pumps, HVAC units, and industrial machinery, unsafe pressure levels can cause severe damage or even pose risks to human safety. This pressure switch acts as a safeguard, ensuring that pressure levels do not exceed dangerous limits.

Durability

Designed for heavy-duty use, the 0533205 hot tub pressure switch is built to last in demanding environments. Its rugged enclosure ensures that the internal components are well-protected from the elements, making it ideal for use in industries where exposure to dust, moisture, and temperature fluctuations is common.

Versatility

The 0533205 pressure switch is highly versatile and can be used in a wide range of applications, from small-scale domestic systems to large industrial machinery. This makes it a valuable component for engineers and system designers who need a dependable and adaptable pressure control solution.

Cost-Effective Solution

While there are many pressure switches on the market, the 0533205 pressure switch offers an excellent balance of affordability and high performance. Its reliability ensures fewer system breakdowns, reducing maintenance costs and system downtime.

Installation and Maintenance of the 0533205 Pressure Switch

Installing the 0533205 Pressure Switch

Installing the 0533205 pressure switch is a relatively simple process, though it should always be carried out by a qualified technician to ensure proper operation. Here are the basic steps involved:

- Determine the Appropriate Location: The pressure switch should be installed in a position where it can accurately measure pressure within the system. Avoid areas with excessive heat, moisture, or vibration that could affect performance.

- Connect to the System: The pressure switch is usually connected via a threaded fitting to the system’s pressure source. Ensure that the fitting is properly sealed to prevent leaks.

- Wiring the Electrical Contacts: The electrical connections on the pressure switch must be wired to the equipment being controlled. This could involve connecting the switch to a compressor, pump, or other machinery.

- Adjust the Pressure Settings: Most pressure switches, including the 0533205, allow for pressure setting adjustments. This enables users to set the pressure at which the switch activates or deactivates the system.

- Test the Installation: Once installed, test the system to ensure that the pressure switch is functioning correctly. Monitor the system’s pressure and ensure that the switch responds at the desired pressure points.

Maintaining the 0533205 Pressure Switch

To ensure the long-term functionality of the 0533205 hot tub pressure switch, regular maintenance is recommended. Here are some tips for maintaining the pressure switch:

- Regular Inspections: Check the pressure switch periodically for signs of wear, corrosion, or damage. If the switch is exposed to harsh environments, more frequent inspections may be necessary.

- Calibrate the Pressure Settings: Over time, the pressure settings may drift, requiring recalibration. Ensure that the pressure switch is calibrated correctly to maintain optimal performance.

- Keep Connections Clean: Ensure that the electrical and mechanical connections are free from dirt, debris, and moisture. Dirty or corroded connections can lead to malfunctioning.

- Replace When Necessary: If the pressure switch shows signs of wear or is no longer functioning properly, it’s important to replace it with a new one to avoid potential system damage or safety hazards.

FAQs About the 0533205 Pressure Switch

What is the purpose of the 0533205 pressure switch?

The 0533205 pressure switch is designed to monitor and control pressure levels within a system. It activates or deactivates an electrical circuit when the pressure reaches a specific threshold, ensuring safe and efficient system operation.

Where is the 0533205 pressure switch commonly used?

The 0533205 pressure switch is commonly used in HVAC systems, water pumps, pneumatic and hydraulic systems, automotive systems, and industrial machinery.

How do I adjust the pressure setting on the 0533205 pressure switch?

Most 0533205 pressure switches allow for manual adjustment of the pressure setting. This is done by turning a set screw or knob that controls the pressure threshold at which the switch activates or deactivates the system.

How often should the 0533205 pressure switch be replaced?

The lifespan of a 0533205 pressure switch depends on the environment and the intensity of its use. Regular maintenance and inspections will help extend its life, but replacement may be needed if the switch becomes unreliable or damaged.

Is the 0533205 pressure switch compatible with all types of systems?

While the 0533205 pressure switch is versatile and compatible with many systems, it is always important to verify its specifications against the requirements of your particular application to ensure proper performance.

Conclusion: The Importance of the 0533205 Pressure Switch

The 0533205 pressure switch is an essential component in a wide range of industrial and commercial applications, from HVAC systems to hydraulic machinery. Its ability to accurately monitor and control pressure levels ensures the safety, efficiency, and longevity of complex systems.

With its durable construction, versatility, and cost-effectiveness, the 0533205 pressure switch remains a popular choice for engineers and system designers looking for reliable pressure control solutions. By understanding its applications, installation requirements, and maintenance procedures, you can ensure that the 0533205 pressure switch provides optimal performance in any system.